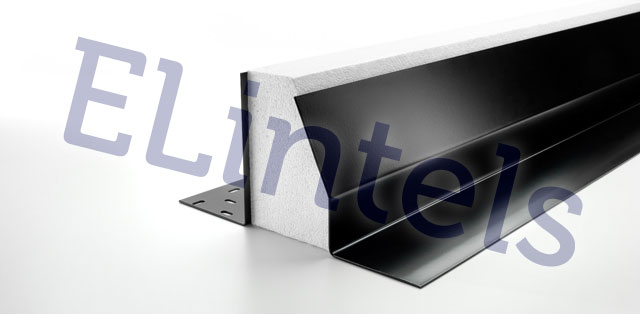

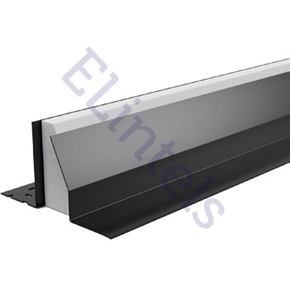

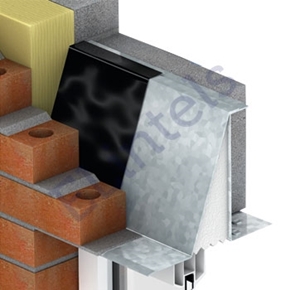

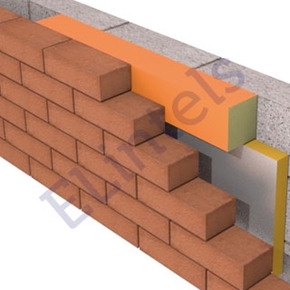

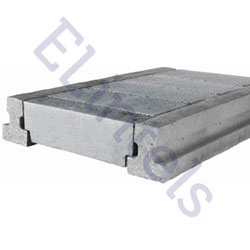

Thermally Broken lintel solution

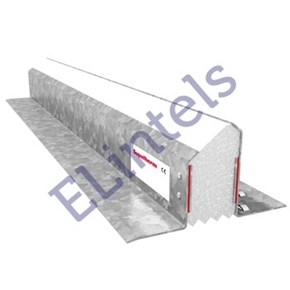

Catnic's latest innovation is the biggest evolution in steel lintel design for a generation. An elegant, simplistic design derived from extensive research and rigorous development testing.

Utilising the strength of steel combined with the thermal insulating properties of a high-density, fire retardent core, it's design provides the thermal performance of seperate lintels, whilst offering users the same stable installations benefits of a traditional cavity wall lintel, providing:

- Industry leading linear thermal transmittance Psi values of 0.02 to 0.05 W/mK

- Safe working loads in line with Catnic's existing cavity wall lintels

- Manufactured from powder coated galvanised steel

- Options are available to suit cavities from 90mm to 165mm, in standard, heavy duty and extra heavy duty performance categories.

Achieving this remarkably low Psi value ensures Catnic's TBL lintel range will always meet the performance criteria requirements of Appendix R found in SAP 2012 providing easy compliance with Part L of the building Regulations.

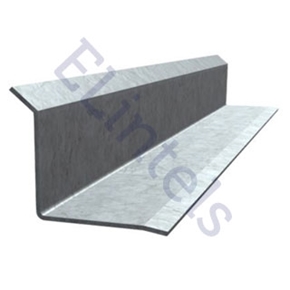

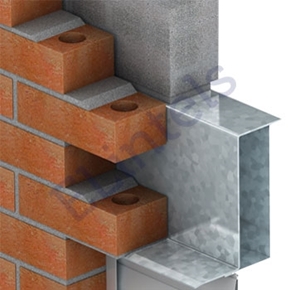

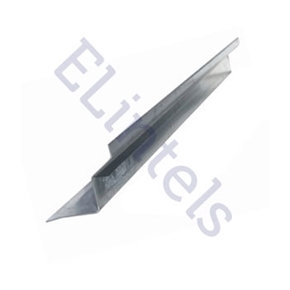

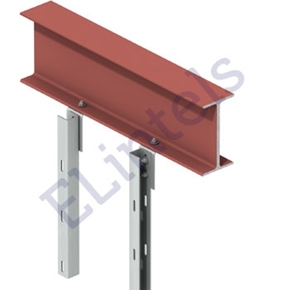

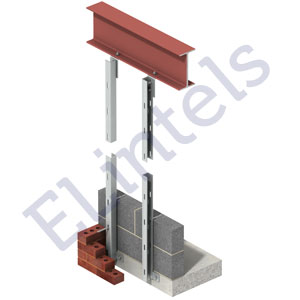

Windposts are designed to offer an alternative, cost effective method of providing the additional stiffness that a masonry wall requires as specified by the Structural Engineer.

Windposts are designed to offer an alternative, cost effective method of providing the additional stiffness that a masonry wall requires as specified by the Structural Engineer.